Rubber compounds for specialized applications

Rubber compounding is a variety of process that results in the different characteristic materials from combining of monomers such as elastomer and fillers, materials such as carbon black or silica. These compounds can be modified to meet the requirements of various applications for example resistance to high temperatures, chemicals or electric conductivity.

Using Silicone Rubber For Manufacturing

Silicon rubber is a great choice for use in manufacturing because it excels in the areas of abrasion resistance and tensile strength. This versatile, high heat material is designed to be used in extreme temperatures. And also, rubber vibration isolator mounts is flexible, toughness and good electrical insulation properties. This also means it is suitable for many applications from automotive gaskets to medical devices.

Advantages of Neoprene use neoprene in custom rubber products

Another popular choice for rubber isolator mounts is neoprene. Its resistance to oil, chemicals and weathering make it a popular material in many applications that requite durability and flexibility. Neoprene is also a good choice for applications that require abrasion resistance and adhere to many substrates. At KFT, we appreciate the features of neoprene and utilize it in our custom rubber solutions to provide superior value and performance for you.

The significance of selecting appropriate elastomers for your application

Choosing the correct elastomer is imperative in a custom rubber manufacturing process. Variety of elastomers have variation on the performance and durability. When selecting an elastomer for a particular application, factors to consider include temperature resistance, chemical compatibility, and mechanical properties. KFT has the knowledge to help you chose the right elastomer for your application, resulting in maximum performance and satisfaction.

Custom rubber molding and material selection

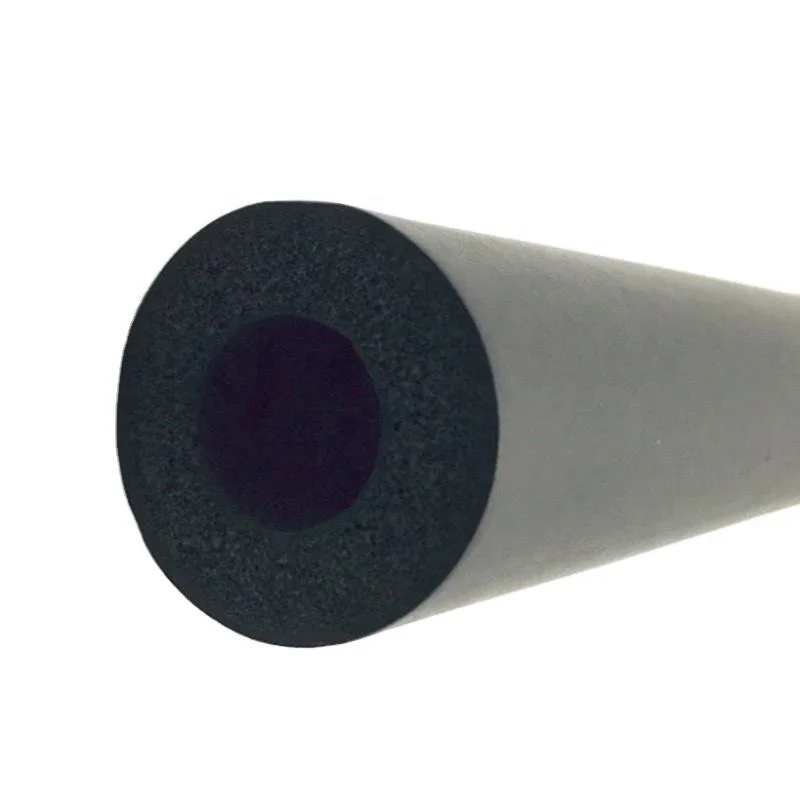

Custom rubber molding manufacturing includes specialized procedures for rubber shock absorber materials into final molded products. Such processes can, for example, include compression molding, transfer molding and/or injection molding which provide different benefits depending on the complexity of the part as well as the properties desired in a molded material. Choosing the right material is important in custom rubber molding and affects how well your product will perform. KFT is a specialist in custom rubber molding and know the most efficient and effective ways to mold your parts, as well offer tips for designing your parts so they are best suited for the type of process used on them.

In brief, rubber parts manufacturing in China means custom materials and different methods which allow the production of high quality parts for use in a range of industries. Using the advantages of silicone rubber, neoprene and other custom compounds, manufacturers such as KFT can create unique solutions often pushing the envelope of what is feasible in a custom rubber product solution. With longstanding tradition of quality, innovation and customer satisfaction, KFT continues to be a reliable partner for industries worldwide in need of high-quality customized rubber services.