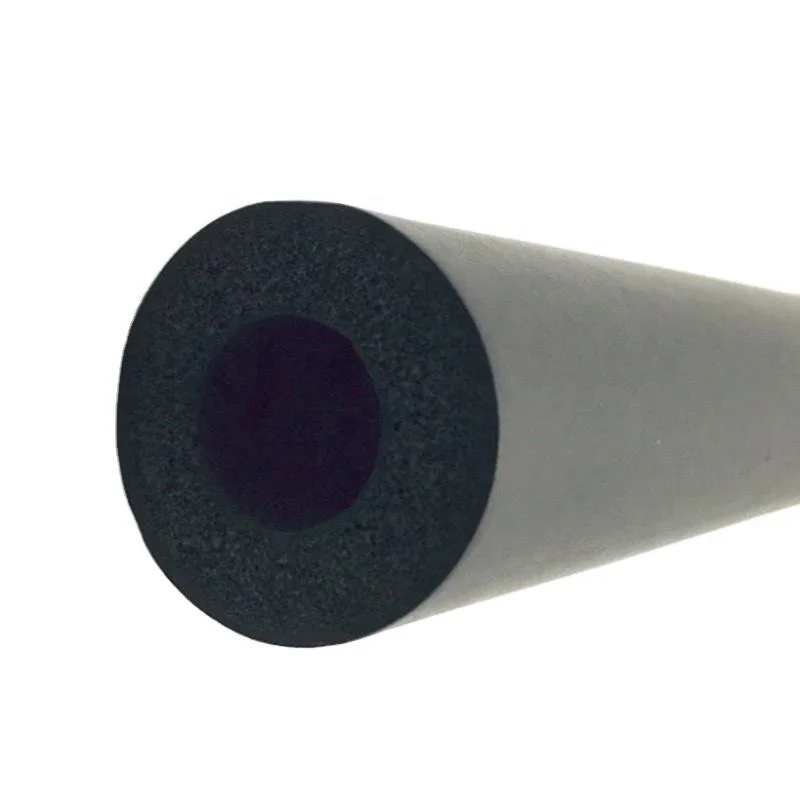

Rubber vibration mounts are special kinds of tools or parts that help to limit the amount of shakes or bounces which occur when a machine is operating. They are constructed out of a type of rubber that is strong and flexible, and they can be a good solution to dampen much of the vibration that industrial equipment normally transfers.

Rubber vibration mounts are essentially mini cushions that machines or equipment sit on. The vibration mounts are also good in helping keep things steady and in place, even when there is a lot of movement. That means the machines can operate more efficiently and safely with less shaking, he added.

There are a lot of advantages of using rubber vibration mounts in industrial machines. For one thing, they can help keep equipment from getting shaken too much. That can save companies a lot of money in repairs and replacements. What’s more, sound levels of machinery can be reduced if it’s installed with KFT anti vibration rubber mount, this can result in a better environment for workers.

There are a couple of considerations to make when you need to select the correct rubber vibration mounts for your need. For starters, you have to consider your equipment’s heft and dimensions. Various vibration isolation mounts are engineered to withstand varying amounts of weight and vibration, so be sure to choose ones that are robust enough to suit your needs. You’ll also want to think about what kind of environment your equipment’s in, since some mounts are a better fit for outdoor use and others are more geared to use indoors.

Rubber vibration mounts are used to dampen noise by absorbing the vibrations which could make machines noise level increase. This could lead to a calmer working environment and help reduce the chances of sound damage for employees. As a bonus, less shaking and bouncing while equipment is in service can do wonders to extend the life of the machinery and rubber vibration mounts can help in that department as well. That would mean less need for companies to replace their equipment, saving them time and money in the long term.

Just like any other products, rubber vibration mounts must be kept and replaced well when time comes. With time, the rubber can break down and lose its ability to damp vibrations. This can cause the machine to shake more or clang to cause damage. Through periodic inspection of mounts and by replacing old mounts they can control equipment to run without defect and high efficiency.

We provide our products working life more than 5-10 years. And we have a comprehensive of after-sales system & effective mechanism to handle quality issue, so ensure that customers are worry free.

The enterprise has independent development ability and advanced process equipment, which can ensure the one-stop service from product design, mold development, manufacturing, processing and packaging.

With the help of advanced ERP system, arrange production schedule and material plan, distribute the production capacity and material, so reduce inventory and optimize the supply chain to improve efficiency and reduce costs for customers.

Shenzhen Kingfund Technology Co., Ltd. is a high-tech enterprise with general taxpayer qualification, which integrates the development, design and manufacture of silica gel, rubber, precision hardware.